-

Vendor:Simpson Strong-Tie

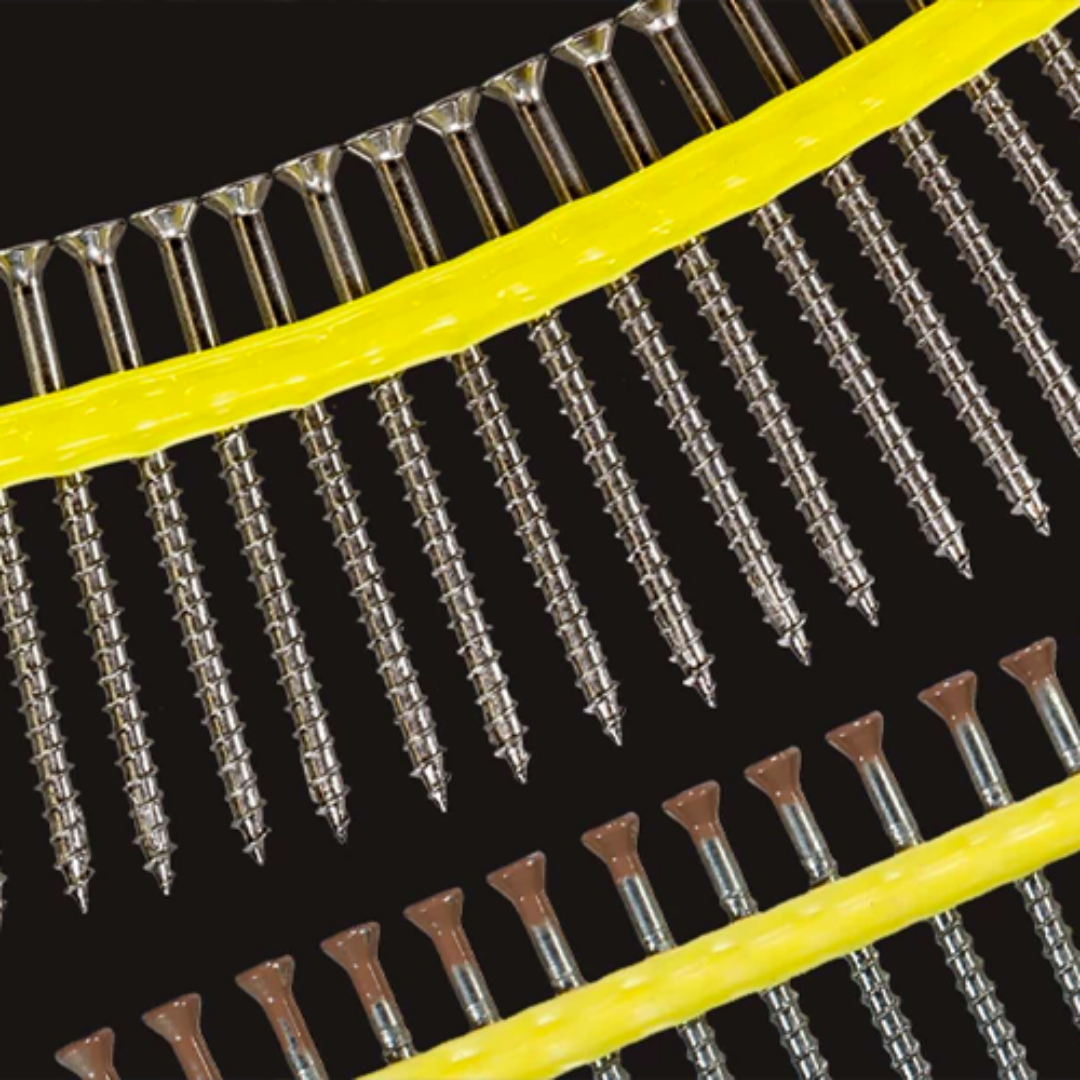

Vendor:Simpson Strong-TieDeck-Drive™ DSV Collated Wood Screw | Coated

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieDeck-Drive™ DSV Deck Screws | Coated

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieDeck-Drive™ DSV Wood Screws | Coated

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieSimpson Strong-Drive® SD Connector Screw | Coated

Regular priceRegular price

Are You a Contractor or Deck Builder?

Sign up with us and register your company with as as a contractor to receive a 5% discount off every order! We'll be sure to send you any additional deals too so you won't miss out on any promotions or new products.

What are Coated Screws?

These are screws that has been treated with a layer of protection to help prevent corrosion. This layer is applied to the exterior of the screw to provide a barrier against the elements and prevent rust and corrosion from forming. The coating can be made from a variety of materials, the most popular being zinc, which is a popular choice for its durability and effectiveness.

Coated screws work well in outdoor applications, such as decking, where they will be exposed to the elements. The coating provides a layer of protection against corrosion, which helps to extend the life of the screw and prevent it from failing prematurely.

Although these screws do prevent corrosion, we recommend stainless steel screws in use cases where they will be frequently exposed to moisture or by the ocean.

Why use Coated Screws?

Coated screws provide a good layer of protection and are much more cost effective than stainless steel screws.

You want a screw that will provide a strong hold in the wood and withstand the elements and coated wood screws offer more than enough protection in general applications. We offer galvanized screws and Quik Guard® coated screws which give a layer of protection against corrosion and helps to extend the life of your project.

What Coatings do we Supply?

Hot-Dip Galvanized Screws

Hot-dip galvanizing offers outstanding corrosion resistance by the simple and effective nature of the process. Steel fasteners are dipped into a bath of molten zinc, forming a coating that is of uniform thickness on all surfaces of the screw or bolt which provides excellent protection even on corners and edges.

While the steel is immersed, a metallurgical reaction occurs between the iron in the steel and the molten zinc. In simple terms there is a tightly bonded zinc-iron alloy coating directly on the surface of the steel screw which in turn is coated by a pure zinc outer layer. This double layers creates an outstanding system for corrosion prevention.

Mechanical Galvanized Screws

Mechanical galvanizing is a metal finishing process performed at room-temperature which involves tumbling the screws to be coated in a drum filled with zinc power, glass beads, and special corrosion inhibiting chemicals. Prior to this process, the screws are very well cleaned and flash-coated with copper.

Simply, the glass beads peen (or beat!) the zinc onto the surface of the screw, hence the term ‘mechanical galvanizing’ as opposed to the chemical reactions which occur in the hot-dip process. This process is most suited to small fasteners with fine threads that would not be suited to hot dipping.

Quik Guard® Coated Screws

Quik Guard® is Simpson Strong-Tie’s proprietary coating system consisting of an electroplated zinc base layer with several organic top coats. The corrosion resistance is equivalent to hot-dip galvanization (ASTM A153, Class D) in some exposures and in most non-marine environments, and described by ICC-ES, AC257 Exposures 1 and 3.

Benefits of Coated Screws

Coated screws offer a number of benefits.

Here are some of the advantages of using coated screws:

Longer lifespan

Coated screws can last longer than uncoated screws, even in harsh environments.

Improved corrosion resistance

Coated wood screws are more resistant to corrosion, which means they can withstand the elements and continue to perform well over time.

Stronger Hold

Coated screws provide a strong hold in the wood, which means they can withstand heavy loads and stresses.

Easy to install

These screws are easy to install and can be used with a variety of types of wood.

Cost-effective

Coated screws are a cost-effective option for your decking or woodworking project, as they can help extend the life of your project and reduce maintenance costs.

The Science Behind Quik Guard Coatings

Quik Guard coatings are a proprietary system that combines the best of both worlds: an electroplated zinc base layer and organic top coats. But what makes them so effective? Let's dive into the details.

Collapsible content

The Electroplated Zinc Base Layer

The Electroplated Zinc Base Layer

The base layer of Quik Guard ®coatings is made up of electroplated zinc, which is applied in accordance with industry standards (ASTM F1941). This process involves depositing a thin layer of zinc onto the surface of the screw using an electric current. The resulting coating is strong, durable, and provides excellent corrosion resistance.

The Organic Top Coats

The Organic Top Coats

But that's not all - Quik Guard® coatings also feature organic top coats that add an extra layer of protection against corrosion. These top coats are carefully formulated to work in conjunction with the electroplated zinc base layer, providing a robust defense against the elements.

Corrosion Resistance

Corrosion Resistance

So, how effective are Quik Guard® coatings? In short, they're incredibly effective. In some exposures, Quik Guard® coatings have been shown to provide corrosion resistance equivalent to hot-dip galvanization (ASTM A153, Class D). This is particularly impressive, given that hot-dip galvanization is widely considered the gold standard for corrosion protection.

Real-World Performance

Real-World Performance

But what about real-world performance? Quik Guard® coatings have been tested in a variety of environments, including those with moderate levels of moisture and salt. The results are impressive: in most non-marine environments, Quik Guard® coatings have been shown to provide excellent corrosion resistance.

Certifications and Compliance

Certifications and Compliance

Quik Guard® coatings have also been certified by reputable third-party organizations, including the International Code Council (ICC-ES). Specifically, Quik Guard® coatings meet the requirements of ICC-ES AC257 Exposures 1 and 3, which cover a range of environmental conditions.

In Summary

In Summary

Quik Guard coatings are a powerful tool in the fight against corrosion. With their electroplated zinc base layer and organic top coats, they provide a robust defense against the elements. Whether you're working on a decking project or building a structure in a harsh environment, Quik Guard coatings are an excellent choice.

Understanding Class D Hot-Dip Galvanization

Collapsible content

What is ASTM A153, Class D?

What is ASTM A153, Class D?

ASTM A153, Class D is a standard specification for zinc coating (hot-dip) on iron and steel hardware. It requires a minimum average of 1.0 oz/ft2 (305 g/m2) of zinc to be applied by a hot-dip process. This coating weight is equivalent to 1.7 mils, providing a robust layer of protection against corrosion.

Compliance with Building Codes

Compliance with Building Codes

Hot-dip galvanized fasteners that meet the requirements of ASTM A153, Class D are compliant with the 2018 and 2021 International Building Code (IBC) and International Residential Code (IRC). This means that builders and contractors can use these fasteners with confidence, knowing that they meet the necessary standards for corrosion resistance.

Use with Preservative-Treated Wood

Use with Preservative-Treated Wood

When working with preservative-treated wood, it's essential to use fasteners that can withstand the corrosive effects of the treatment. According to the IBC and IRC, hot-dipped galvanized steel fasteners that comply with ASTM A153 are permitted for use with preservative-treated wood. In fact, the Western Wood Preservers Institute (WWPI) recommends using hot-dipped galvanized fasteners that meet the requirements of IBC Section 2304.9.5.

Mixing Fasteners: What to Avoid (WARNING!)

Mixing Fasteners: What to Avoid (WARNING!)

When using hot-dipped galvanized steel fasteners, it's crucial to avoid mixing them with other types of fasteners. Hot-dipped galvanized steel and stainless steel should not be used together, as this can lead to galvanic corrosion. Instead, use fasteners with the same coatings to ensure compatibility and prevent corrosion.

NRCA Recommendations

NRCA Recommendations

The National Roofing Contractors Association (NRCA) also provides guidelines for using preservative-treated wood. According to their recommendations, hot-dipped galvanized fasteners that comply with ASTM A153 and connectors that comply with ASTM A653, Class G185, are generally acceptable. However, for maximum corrosion resistance, Type 304 or Type 316 stainless-steel fasteners and connectors are recommended.

In Summary

In Summary

Class D hot-dip galvanization is a reliable method for protecting steel fasteners from corrosion. By meeting the requirements of ASTM A153, these fasteners are compliant with building codes and suitable for use with preservative-treated wood. Remember to use fasteners with the same coatings and avoid mixing different types to ensure compatibility and prevent corrosion.