-

Vendor:Eagle Claw Fasteners

Vendor:Eagle Claw FastenersStainless Steel Wood Screws | 304/305 Grade

Regular priceRegular price -

Vendor:Eagle Claw Fasteners

Vendor:Eagle Claw FastenersStainless Steel Decking Screws | 316 Grade

Regular priceRegular price -

Vendor:Eagle Claw Fasteners

Vendor:Eagle Claw FastenersStainless Steel Decking Screws | 304 Grade

Regular priceRegular price -

Vendor:Eagle Claw Fasteners

Vendor:Eagle Claw FastenersStainless Steel Wood Screws | 316 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieStrong-Drive Heavy Duty DWP Stainless Steel Screws | 316 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieDeck-Drive® DWP Stainless Steel Deck Screws | 316 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieStrong-Drive® DWP Stainless Steel Wood Screw | 316 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

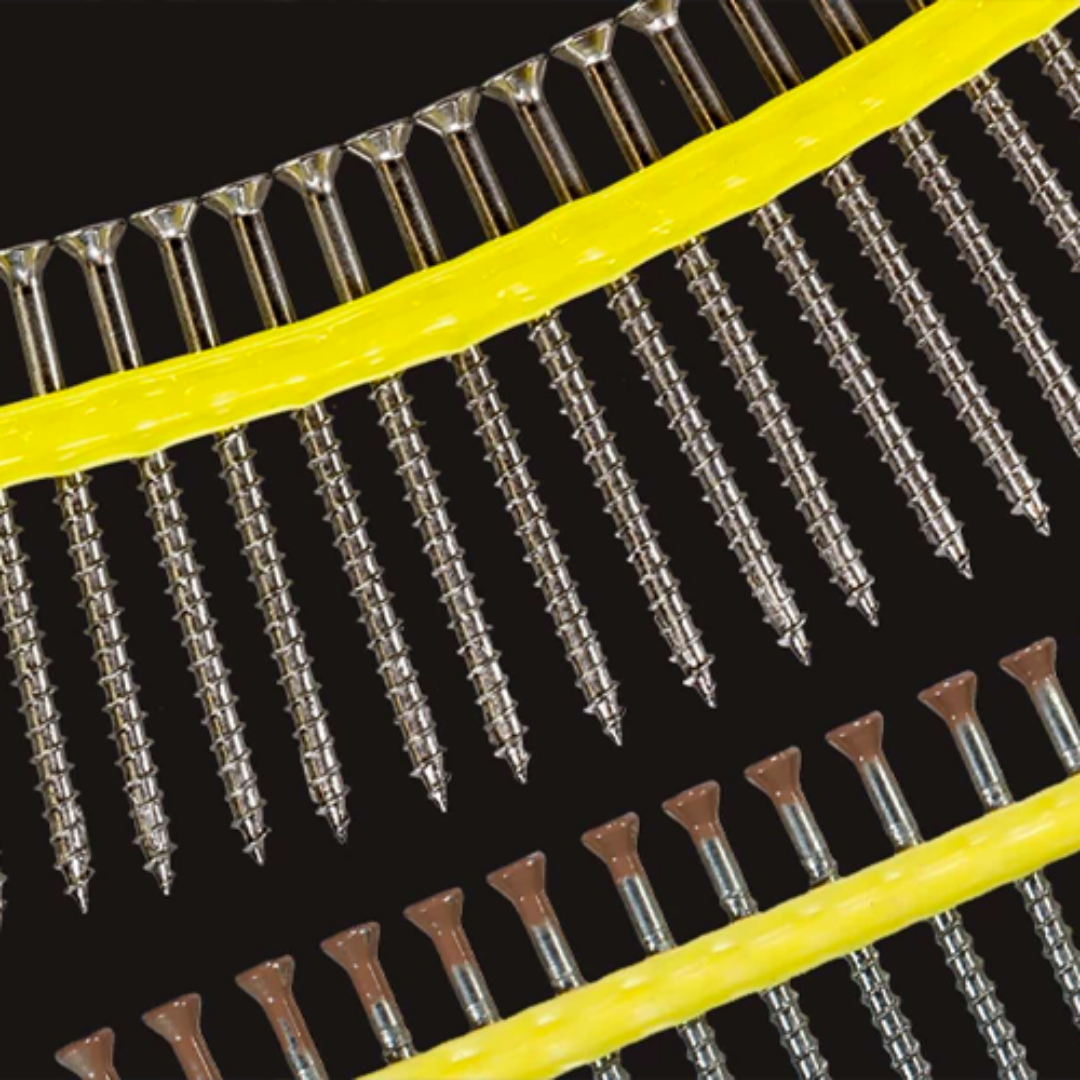

Vendor:Simpson Strong-TieDeck-Drive™ DWP Stainless Steel Collated Screws | 305 Grade

Regular priceRegular price -

-$15.95

Vendor:Eagle Claw Fasteners

Vendor:Eagle Claw FastenersStainless Steel Wood Screws Value Pack | 304 Grade

Regular price $69.95Regular price$85.90-$15.95 Sale price $69.95 -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieDeck-Drive™ DHPD Hardwood Decking Screw | 305 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieDeck-Drive™ DWP Stainless Steel Collated Screws | 316 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieStrong-Drive® SDS Heavy Duty Hex Connector Screw | 316 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieStrong-Drive® SDWH Timber-Hex Stainless Steel Screw | 316 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieStrong-Drive® SDWS Structural Stainless Steel Screw | 316 Grade

Regular priceRegular price -

Vendor:Simpson Strong-Tie

Vendor:Simpson Strong-TieStrong-Drive® Stainless DWP Wood Screw | 305 Grade

Regular priceRegular price

Are You a Contractor or Deck Builder?

Sign up with us and register your company with as as a contractor to receive a 5% discount off every order! We'll be sure to send you any additional deals too so you won't miss out on any promotions or new products.

Stainless Steel Screws

Stainless steel screws are made from corrosion-resistant steel alloys and offer high strength, durability, and resistance to corrosion, making them ideal for applications that would otherwise destroy a regular coated screw such as costal projects.

If you are working in industries such as construction, marine, and manufacturing, where exposure to harsh environments is common, then we would highly recommend stainless steel screws, however, if conditions are not humid or damp, then coated screws would do just fine - even though they will eventually rust away (unlike stainless screws)

We offer these screws in a range of sizes, shapes, and grades, making them suitable for a wide range of applications - Whether you're building a deck, repairing a boat, or assembling furniture, stainless steel screws are an excellent choice.

Materials and Grades

There are many different grades of stainless steel screws that have been introduced to cater to specific needs with the most common being 304, 305 and 316 grades.The choice of grade depends on the specific application and environment.

Grade 304 is the most widely used and is known for its excellent corrosion resistance and durability. Grade 305 is basically the same as 304 but is ever so slightly more resistant to corrosion. Grade 316, on the other hand, is known for its high corrosion resistance and is often used in ship building, decking buy the ocean, marinas, and even in chemical factories.

The choice of grade depends on the specific application and environment. For example, grade 304 and 305 is suitable for general-purpose applications where longevity is important, while grade 316 is recommended for applications where high corrosion resistance is required. It's essential to choose the right grade of stainless steel screw to ensure optimal performance and longevity.

Don't get us wrong though - 304/305 grade stainless steel screws are not far off the corrosion resistance of 316 and the likelyhood that they will corrode is minimal.

Benefits of Using Stainless Steel Screws

Corrosion resistance

Stainless steel screws are highly resistant to rust and corrosion, making them ideal for use in environments that are damp, humid, salty or otherwise corrosive.

Durability

They can withstand heavy loads and stresses, making them suitable for demanding applications.

Low maintenance

They do not require regular cleaning or coating, as they are resistant to corrosion and can withstand exposure all kinds of weather and environments. Stainless steel screws outlast the timber used in the project 99% of the time.

Versatile for any project

Stainless steel screws are highly versatile and can be used with a variety of hardwoods and softwoods, including pressure-treated lumber, cedar, and composite decking materials. This makes them an ideal choice for any decking project, whether you're building a new deck or repairing an existing one.

Common Uses and Projects

Due to the key points stated above, stainless steel screws are commonly used in various projects, including:

- Deck building

- Fence installation

- Furniture making and restoration.

- Boat building

- Construction and renovation projects.

- DIY projects, such as building a treehouse, play yard, or birdhouse.

Why are Stainless Steel Screws the Best Choice?

Stainless steel deck screws are the best choice for any decking project. They are made from a corrosion-resistant alloy that can withstand the harsh outdoor elements, including rain, snow, and saltwater. This means that your deck will remain safe and secure, without the risk of screws rusting or failing. Plus, stainless steel screws are resistant to warping and bending, ensuring that your deck boards remain tightly secured.

Where to use

Stainless Steel Wood Scews

Decking

Decking

Stainless steel deck screws are the way to go for your deck-building project! They offer excellent corrosion resistance, strength, and durability, making them a top choice for any outdoor job.

Unlike traditional galvanized or coated screws, stainless steel screws are resistant to rust and can withstand all weather conditions, including saltwater and high humidity. This makes them an ideal choice for decks located near the ocean or in areas with high rainfall.

Not only will stainless steel decking screws provide a safer and more durable deck, but they'll also require minimal maintenance, as they're resistant to corrosion and don't need to be coated or treated.

When it comes to decking screws, we always recommend stainless steel due to their durability AND, they have the added benefit of having a sleek, modern appearance that complements any deck design.

Costal Construction

Costal Construction

Stainless steel really does stand the test of time when it comes to weather resistance but sometimes screws don't have the holding power that you need. This is where our stainless steel hex cap screws come in to their own. The holding power of these lag screw alternative are well worth it and will ensure that your structure is be there to stay.

The hex head lag bolt are often used directly on piers, docks, jetties and other structures that come into direct contact with the ocean or water in general and what we have found is that the stainless steel lag bolts themselves have outlasted the structures.

Outdoor Projects

Outdoor Projects

There are times when regular coated screws are not going last long in your pergola project and that is when we would recommend stainless steel wood screws - especially in costal regions. Stainless steel is the only screw that is worth using in areas such as Florida and California for example.

Because of the corrosion-resistant properties of these screws, they are an excellent choice for applications where durability and longevity are essential. This makes them perfectly suited for outdoor structures such as decks, pergolas, fences, playground equipment, and boardwalks, where exposure to the elements can lead to accelerated corrosion.

The last thing anyone wants is your structure collapsing on someone because the screws have rusted away.